Test Decoiler OZ-1250/5 Bří Švarcové

SKU 134135138

0 reviews

In stock

BRI SVARCOVE

Shipping

- Self pick up Free

- Nova Poshta at the price of NP

- Meest at the price of Meest

Payment

- Post-payment

- Cash

- Payment by invoice

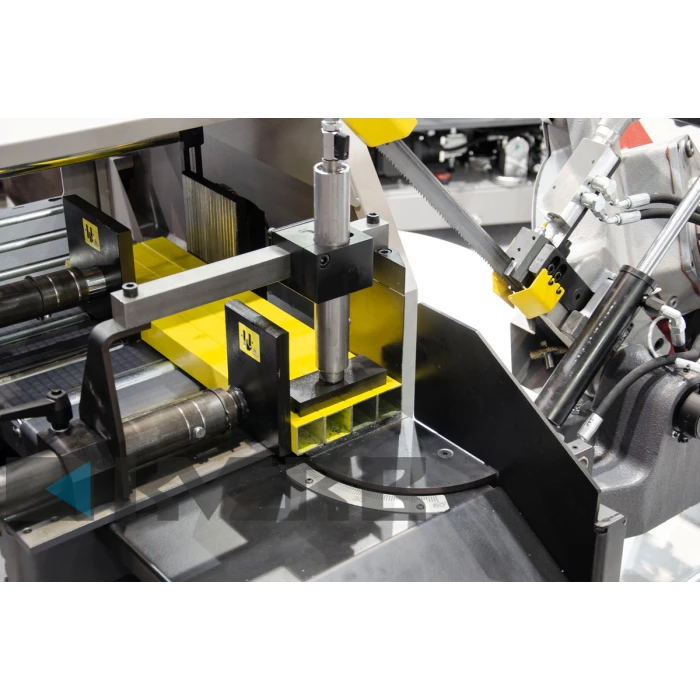

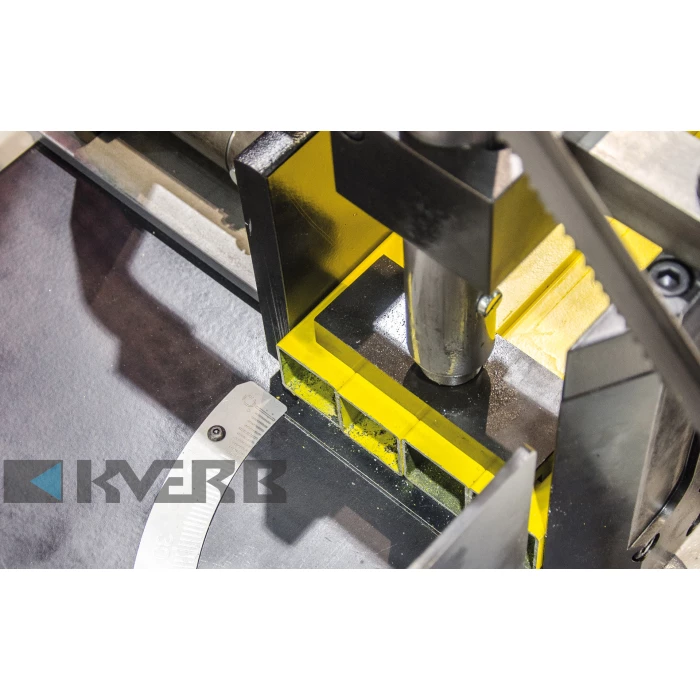

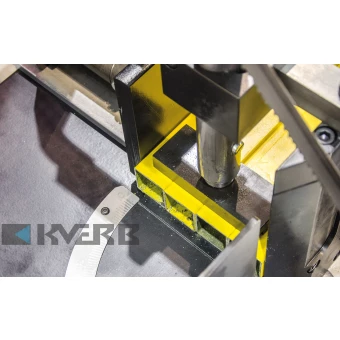

Decoiler OZ-1250/5 Bří Švarcové is a modern and efficient device designed for unrolling metal coils with thicknesses of 0.6 mm and 0.8 mm. The main design feature is the spindle, which inserts into the inner diameter of the coil and is secured with a key, ensuring stability and uniform unrolling. The rounded surface between the coil and spindle prevents mechanical damage to the metal, which is especially important for further processing of the material.

OZ-1250/5 Bří Švarcové has the following key specifications:

Maximum load capacity is 5000 kg. This decoiler can handle loads of up to 5 tons, making it ideal for working with heavy metal coils. It is a perfect solution for large-scale production facilities dealing with thick metal coils or working with large volumes of material. The high load capacity ensures safe operation and stability during the unrolling process.

Maximum coil width is 1250 mm. The device is designed to work with coils up to 1250 mm wide, which is a universal standard in the metalworking industry, enabling work with most types of rolled metal used in roofing material production, corrugated sheets, and facade panels.

Minimum coil diameter is 430 mm. The decoiler supports work with coils having a minimum diameter of 430 mm, making it suitable for compact metal coils. This is especially important for enterprises working with different formats of rolled steel and non-ferrous metals.

Maximum coil diameter is 520 mm. The decoiler is capable of working with coils up to 520 mm in diameter, which complies with standard industrial requirements. This ensures compatibility with a wide range of rolled materials used in manufacturing metal structures, facade panels, ventilation systems, and other products.

OZ-1250/5 Bří Švarcové has several important advantages:

Protection of the metal from damage – the rounded surface between the coil and spindle minimizes the risk of material damage.

Flexibility in use – the option to choose between fixed supports or mobile wheels for ease of operation.

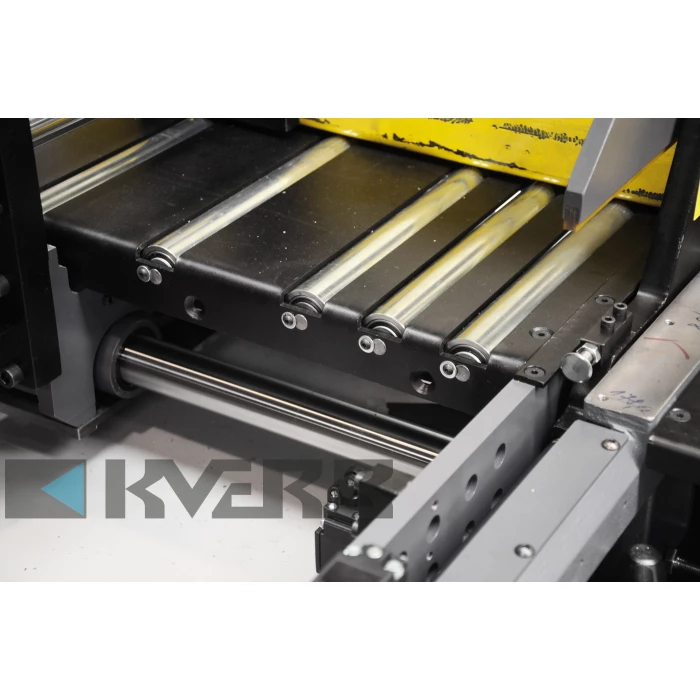

Easy and convenient loading – the open frame design allows easy loading of coils using a forklift.

Controlled unrolling – the braking mechanism and control wheel allow precise regulation of speed and tension.

Compatibility with TK-1250 – using the decoiler with the cutting device TK-1250 expands functionality for longitudinal and transverse metal cutting.

Decoiler OZ-1250/5 Bří Švarcové is designed to automate and optimize the process of feeding rolled metal into the production cycle. Thanks to the reliable fixation of the coil and the ability to adjust the metal tension, the operator has full control over the process. This equipment significantly increases productivity, reduces time costs, and prevents defects that can arise from uneven unrolling.

OZ-1250/5 Bří Švarcové is an indispensable piece of equipment for businesses engaged in:

Manufacturing corrugated sheets, metal roofing tiles, and roofing materials.

Producing facade panels, ventilation systems, and metal structures.

Working with sheet metal in various industries and construction sectors.

You can purchase decoiler OZ-1250/5 Bří Švarcové at KVERB. We specialize in supplying modern equipment for metal and wood processing, as well as generators and charging stations. Our catalog includes a wide range of products for various industries, including metal presses, woodworking machines, metal cutting saws, rolling machines, sheet benders, tube benders, and magnetic lifting systems. We offer favorable cooperation terms, fast delivery, and expert consultations from our specialists.

Find everything you need for your work on the KVERB website.

OZ-1250/5 Bří Švarcové has the following key specifications:

Maximum load capacity is 5000 kg. This decoiler can handle loads of up to 5 tons, making it ideal for working with heavy metal coils. It is a perfect solution for large-scale production facilities dealing with thick metal coils or working with large volumes of material. The high load capacity ensures safe operation and stability during the unrolling process.

Maximum coil width is 1250 mm. The device is designed to work with coils up to 1250 mm wide, which is a universal standard in the metalworking industry, enabling work with most types of rolled metal used in roofing material production, corrugated sheets, and facade panels.

Minimum coil diameter is 430 mm. The decoiler supports work with coils having a minimum diameter of 430 mm, making it suitable for compact metal coils. This is especially important for enterprises working with different formats of rolled steel and non-ferrous metals.

Maximum coil diameter is 520 mm. The decoiler is capable of working with coils up to 520 mm in diameter, which complies with standard industrial requirements. This ensures compatibility with a wide range of rolled materials used in manufacturing metal structures, facade panels, ventilation systems, and other products.

OZ-1250/5 Bří Švarcové has several important advantages:

Protection of the metal from damage – the rounded surface between the coil and spindle minimizes the risk of material damage.

Flexibility in use – the option to choose between fixed supports or mobile wheels for ease of operation.

Easy and convenient loading – the open frame design allows easy loading of coils using a forklift.

Controlled unrolling – the braking mechanism and control wheel allow precise regulation of speed and tension.

Compatibility with TK-1250 – using the decoiler with the cutting device TK-1250 expands functionality for longitudinal and transverse metal cutting.

Decoiler OZ-1250/5 Bří Švarcové is designed to automate and optimize the process of feeding rolled metal into the production cycle. Thanks to the reliable fixation of the coil and the ability to adjust the metal tension, the operator has full control over the process. This equipment significantly increases productivity, reduces time costs, and prevents defects that can arise from uneven unrolling.

OZ-1250/5 Bří Švarcové is an indispensable piece of equipment for businesses engaged in:

Manufacturing corrugated sheets, metal roofing tiles, and roofing materials.

Producing facade panels, ventilation systems, and metal structures.

Working with sheet metal in various industries and construction sectors.

You can purchase decoiler OZ-1250/5 Bří Švarcové at KVERB. We specialize in supplying modern equipment for metal and wood processing, as well as generators and charging stations. Our catalog includes a wide range of products for various industries, including metal presses, woodworking machines, metal cutting saws, rolling machines, sheet benders, tube benders, and magnetic lifting systems. We offer favorable cooperation terms, fast delivery, and expert consultations from our specialists.

Find everything you need for your work on the KVERB website.

Specifications Test Decoiler OZ-1250/5 Bří Švarcové

- Drive Type (Manual, Electromechanical) Manual

- Metal processing thickness. mm 5000 kg

- Engine power kW -

- Working depth, mm -

- Roll gauge,mm 1250 mm

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21