Test Decoiler AC-125/1000 Bří Švarcové

SKU 134135135

0 reviews

In stock

BRI SVARCOVE

Shipping

- Self pick up Free

- Nova Poshta at the price of NP

- Meest at the price of Meest

Payment

- Post-payment

- Cash

- Payment by invoice

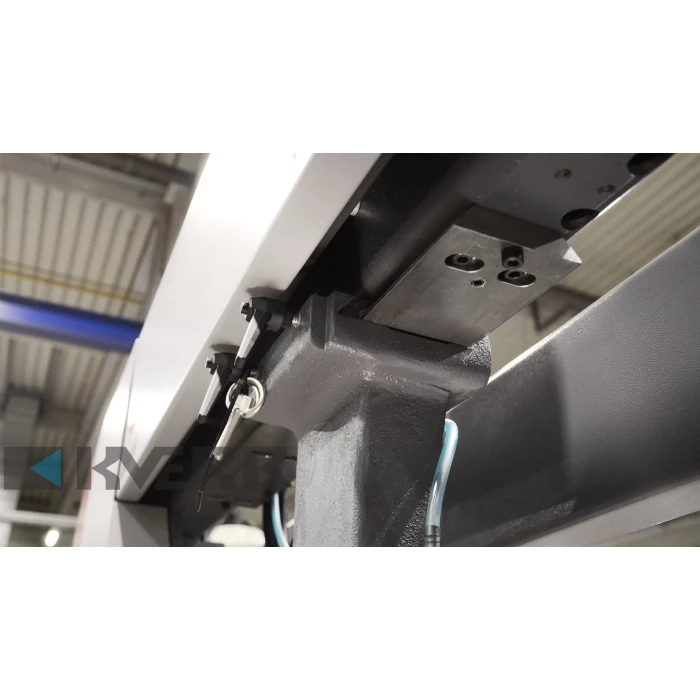

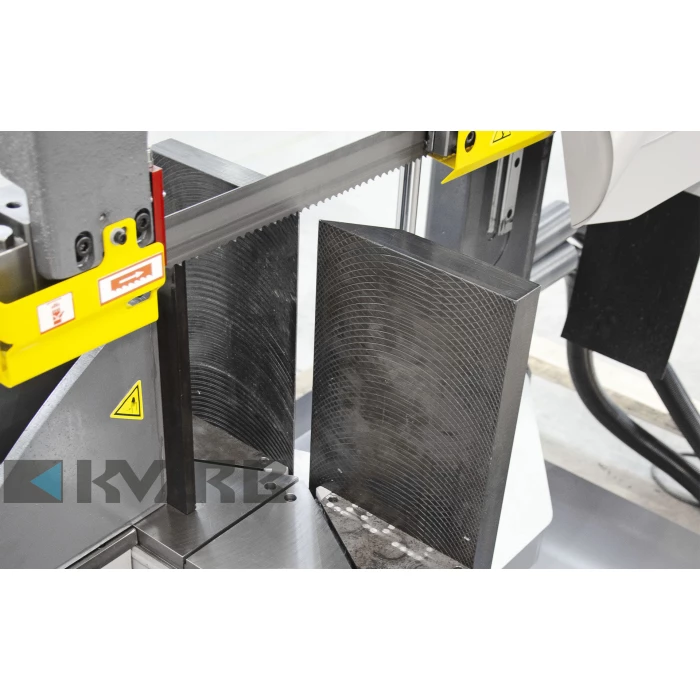

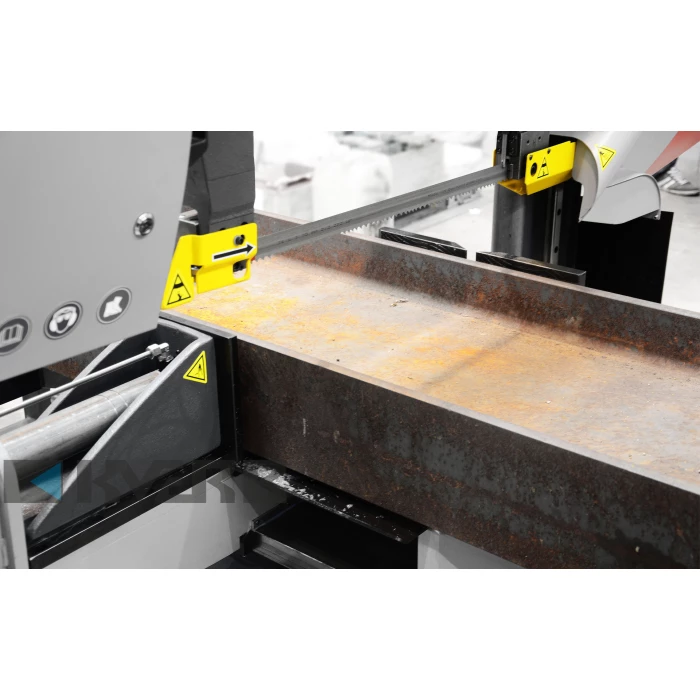

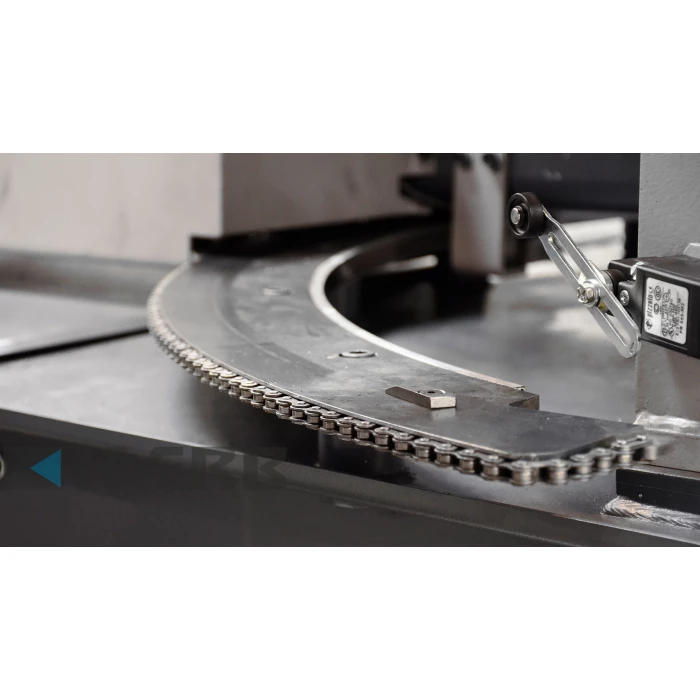

Decoiler AC-125/1000 Bří Švarcové is modern equipment designed for unrolling metal coils weighing up to 1000 kg. It allows for easy and effortless unrolling of coils with a width of up to 1250 mm, significantly speeding up the further processing of metal. Thanks to its sturdy design and convenient fixation system, this decoiler is an excellent choice for businesses working with sheet metal.

Main characteristics of Decoiler AC-125/1000 Bří Švarcové:

The distance between rollers is 260–330 mm. The decoiler is equipped with an adjustable distance between rollers, allowing it to adapt to different types of metal coils. This ensures smooth and uninterrupted unrolling of both narrow and wider coils.

The maximum length of sheet metal coil is 1250 mm. The device supports coils with a width of up to 1250 mm, which corresponds to the standard dimensions of rolled metal. This is the optimal length for producing products such as corrugated sheet metal, metal roofing tiles, ventilation ducts, and drainage systems.

The maximum weight of sheet metal coil is 1000 kg. The decoiler can handle a load of up to 1000 kg, allowing for the processing of heavy coils without the need for frequent reloading of new material. This increases productivity and reduces machine downtime.

Advantages:

High load capacity handles coils up to 1000 kg, allowing for the processing of large coils.

Different versions available in two versions: on swivel wheels with brakes or with stationary supports.

Easy transportation the sturdy frame makes it easy to move the decoiler using a forklift or hydraulic trolley.

Compatibility with other devices when paired with TK-1250, it forms an efficient system for working with rolled metal.

Decoiler AC-125/1000 Bří Švarcové ensures effective and uninterrupted work with coil material. It will become an indispensable piece of equipment for businesses involved in:

Manufacturing roofing materials such as corrugated metal, metal roofing tiles.

Production of ventilation systems and air ducts.

Processing sheet metal to create facade panels, drainage systems, and metal profiles.

Other types of metalworking that require working with coil materials.

This model can be used in conjunction with other devices for cutting, bending, or shaping metal, making it a versatile assistant in the production process.

You can purchase decoiler AC-125/1000 Bří Švarcové at KVERB. We offer a wide range of professional equipment for metal and wood processing, as well as generators and charging stations. Our selection includes metal presses, woodworking machines, metal cutting saws, rollers, sheet metal benders, pipe benders, lifting systems, seam rolling machines, rolling lines for the production of drainage systems, welding tables, and grinding machines.

Main characteristics of Decoiler AC-125/1000 Bří Švarcové:

The distance between rollers is 260–330 mm. The decoiler is equipped with an adjustable distance between rollers, allowing it to adapt to different types of metal coils. This ensures smooth and uninterrupted unrolling of both narrow and wider coils.

The maximum length of sheet metal coil is 1250 mm. The device supports coils with a width of up to 1250 mm, which corresponds to the standard dimensions of rolled metal. This is the optimal length for producing products such as corrugated sheet metal, metal roofing tiles, ventilation ducts, and drainage systems.

The maximum weight of sheet metal coil is 1000 kg. The decoiler can handle a load of up to 1000 kg, allowing for the processing of heavy coils without the need for frequent reloading of new material. This increases productivity and reduces machine downtime.

Advantages:

High load capacity handles coils up to 1000 kg, allowing for the processing of large coils.

Different versions available in two versions: on swivel wheels with brakes or with stationary supports.

Easy transportation the sturdy frame makes it easy to move the decoiler using a forklift or hydraulic trolley.

Compatibility with other devices when paired with TK-1250, it forms an efficient system for working with rolled metal.

Decoiler AC-125/1000 Bří Švarcové ensures effective and uninterrupted work with coil material. It will become an indispensable piece of equipment for businesses involved in:

Manufacturing roofing materials such as corrugated metal, metal roofing tiles.

Production of ventilation systems and air ducts.

Processing sheet metal to create facade panels, drainage systems, and metal profiles.

Other types of metalworking that require working with coil materials.

This model can be used in conjunction with other devices for cutting, bending, or shaping metal, making it a versatile assistant in the production process.

You can purchase decoiler AC-125/1000 Bří Švarcové at KVERB. We offer a wide range of professional equipment for metal and wood processing, as well as generators and charging stations. Our selection includes metal presses, woodworking machines, metal cutting saws, rollers, sheet metal benders, pipe benders, lifting systems, seam rolling machines, rolling lines for the production of drainage systems, welding tables, and grinding machines.

Specifications Test Decoiler AC-125/1000 Bří Švarcové

- Drive Type (Manual, Electromechanical) Manual

- Metal processing thickness. mm 1000 kg

- Engine power kW -

- Working depth, mm -

- Roll gauge,mm 1250 mm

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21